large format bed laser cutter machine for sale

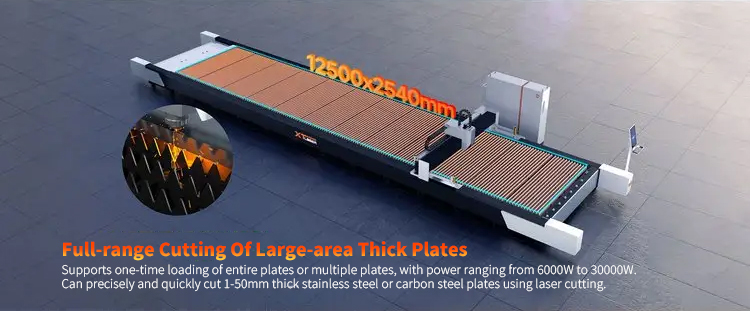

Large format metal laser cutting machine, large workbench, suitable for laser equipment above 3000w, the format can be customized.

The cutting speed of big laser cutting machine is twice that of carbon dioxide laser cutting machine with the same power.

Power:3000w 6000w 10kw 12kw 15kw 20kw 30kw 60kw

Introduction

The large bed laser cutter is suitable for cutting large-format metal sheets in the industrial market, saving time and improving work efficiency. It adopts gantry structure machine tools, aluminum alloy beams, high-precision grinding helical gear racks, high-precision linear It is a high-tech product that uses a combination of professional cutting CNC systems. In terms of cutting, large-format laser cutting machines have the characteristics of fast cutting speed and low maintenance costs.

large bed laser cutter video

14031 large format laser cutting machine

12000w universal large laser cutter

Technical Parameters

- Brand: Dowell Laser

- Power: 3000w-60kw

- Working width (mm):12000*2500

- Workbench load: 10000kg

- Positioning accuracy: ±0.03mm/m

- Repeat positioning accuracy: ±0.02mm/m

- Maximum speed: 120m/min

- Customizable designs

- Maximum acceleration: 1.2G

- Power supply: three-phase 380V/50/60Hz

- Production place: China

- Customizable super large format

Features & Advantages

- The base of the machine tool is thick and stable, stable and reliable during high acceleration.

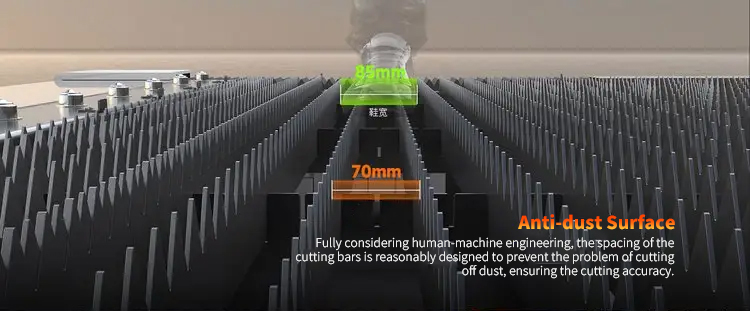

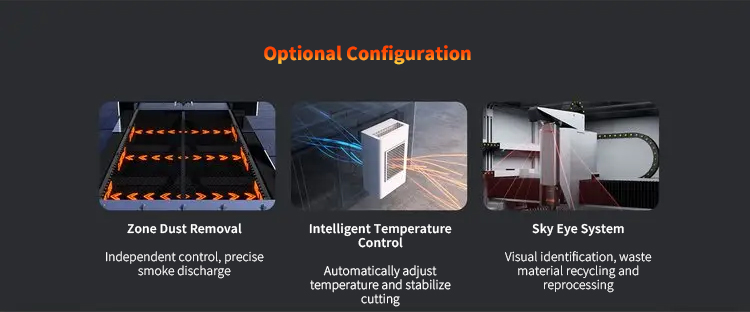

- It adopts multi-channel automatic partition dust removal at the bottom and a smoking structure at the top, so that the smoke and dust have nowhere to hide.

- Automatic lubrication and refueling, even and consistent refueling, eliminating the trouble of manual refueling

- The switching station has fast switching speed, simple structure, low failure rate and easy maintenance.

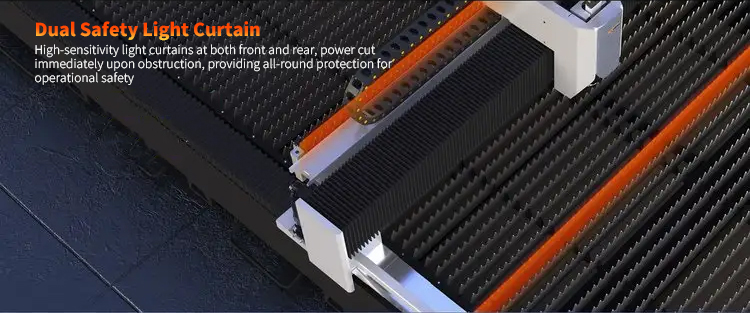

- The whole machine is fully sealed and safe.

- A scrap cart is installed at the bottom of the cutting area and can be pulled out regularly.

Clean up waste:

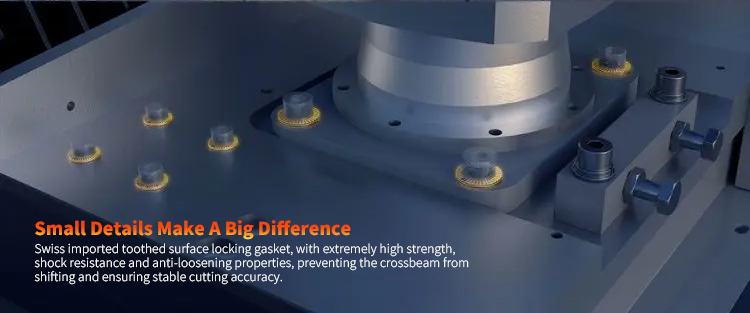

Crossbeam part:

The beam adopts lightweight casting structure, which is rough machined after annealing to eliminate internal stress, and finished after secondary vibration aging treatment, which can better solve the stress caused by casting and processing, thus greatly improving the stability of the machine tool.

Z-axis device, air path:

The system reads the Z-axis capacitive sensor to detect the distance signal, thereby accurately controlling the height of the cutting head and the board surface to ensure that the cutting quality is affected by uneven cutting materials. The gas circuit for cutting the foot is divided into oxygen, air, and nitrogen, and the gas can be switched freely. The gas component is a customized SMC brand imported from Japan. The air pressure control has high precision and good stability.

application

Due to its large processing range, high processing accuracy and quality, strong adaptability and flexibility, large bed laser cutter can be widely used in various industries and fields, such as aerospace, automobile , agricultural machinery, electrical equipment, architectural decoration, home appliance.

How Much is large format laser cutter price

The price of large format laser cutter is generally around 41685.78–147289.76 US dollars, the higher the power, the higher the price, which is related to branding impression, manufacturer strength, configuration, power size and so on.

Contact us to get the latest large format laser cutting machine prices and recommend a suitable big laser cutting machine for you.

FAQ

wholesale best large format chinese laser cutter factory

how large is a laser cutte bed

Products produced by large format laser cutter suppliers: 3-4 meters long, 2-3 meters wide, 1.5-2 meters high.

What can diy large format laser cutter do?

Large format laser cutter suppliers reduce the measurement load by installing the laser at the bottom of the machine tool, and configure a special constant optical path compensation design to achieve high-speed and high-precision cutting and engraving integrated functions. It is suitable for clothing textiles, packaging materials, automotive interiors, and non-woven fabrics. , leather and other industries. It can also be equipped with automatic feeding and feeding mechanisms according to customer requirements to realize automated cutting processes.

Can large wood laser cutter cut metal?

No, wood laser equipment can only be used to cut wood and non-metallic materials.

Can large size 3000 watt laser cutter factories customize products?

DOWELL laser cutting equipment manufacturers can customize their products according to customer needs.

the difference laser cutter beam larger horizontal vs vertical

Accuracy is different

The cutting accuracy of vertical intersecting is relatively high, which can ensure the precise position of the cutting point. Because the cutting point is on the workpiece surface, when the laser beam is parallel to the workpiece surface, refraction and scattering will cause the beam to bend, causing the cutting point to deviate. Vertical intersection can reduce the occurrence of this error and increase cutting accuracy.

Different cutting speeds

Horizontal intersection increases cutting speed. Because horizontal intersection can reduce the distance that the laser beam passes through the workpiece, reduce the residue generated during cutting, and improve efficiency. Vertical intersection requires more cutting time and energy, and the speed is relatively slow.

Cutting thickness varies

Horizontal intersecting is suitable for cutting thicker materials. Because horizontal intersection can reduce the contact area between the laser beam and the workpiece surface, reducing damage to the workpiece, thereby achieving cutting of thicker materials. Vertical intersection is not suitable for cutting materials that are too thick, because cutting needs to go through the entire workpiece, which requires more time and energy.